A Ukrainian manufacture with full cycle located in Kyiv

Services of laser cutting, machine embroidery, development and design of soft toys, printing on fabric are available both within production and separately.

MANUFACTURING DEPARTMENTS

R&D is the development and design department. This department is the heart of the factory, where professional designers realize your every wishes with the most accurate reproduction in the product.

R&D is a closed secret department that has its own industrial equipments for a full cycle of production that allows us to perform inside department without destroy the main production line. R&D services:

Послуги R&D:

Model sketch

Sewing a master model

Material selection

Development of technical specifications for materials and equipment for for further sewing

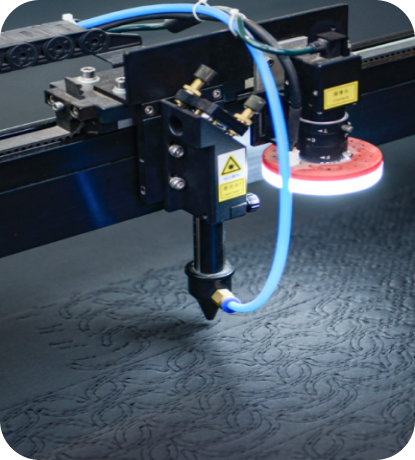

Cutting with perfect precision to 0.02 cm and almost no residue is the skill of our laser cutting department.

The department is equipped with 4 laser cutting machines and can handle many types of material.

What can we do? Cut, perforate, or engrave the following types of material:

Felt

Cardboard

Textile

Foam rubber

Plastic up to 6 mm

Plywood up to 6 mm

Plexiglas up to 6mm (intended for cutting)

When the specific material is not allowed to be cutted in the laser machine, WP Merchandise professionals are making it manually, with maximum cut evenness and fast.

Manual cutting department equipped with industrial saber and band knives.

The maximum allowable thickness

is 60 sheets.

The maximum allowable size is 180 cm.

The embroidery department is powered by modern industrial equipment, where 25 products can be embroidered simultaneously. The embroidery specialists provide services from design layout development to embroidery execution.

There has never been an order that could not be fulfilled by the highly qualified employees of the department.

Reproduce the most detailed pattern on the canvas using threads from monochromatic to luminescent.

Embroidery options:

multilayer applications

classic embroidery (satin stitch and tatami)

3D embroidery using a special three-dimensional material

The factory has three sewing workshops, and each is supplied with modern professional equipment, including multifunctional, which performs three operations: sewing parts, cutting off excess material and simultaneously edging.

This allows to distribute labor and have a fairly flexible production line, which in turn affects the speed and quality of order fulfillment.

Equipment:

Tacking machines

Loop stitching machines

Flat lock machines

Universal equipment

Five-thread overlocks

Four-thread overlockers

Toy decoration starts from the process of filling the skin with sintepuh to attaching accessories, dressing, fastening buttons, adding accessories and decorating.

This is the department that transforms the preparations into a finished item and gives individuality to each product.

Sometimes the smallest detail of a plush figure can be up to 5 mm, and the department's craftsmen skillfully attach it in place.

We use stuffing materials that are not capable of causing allergies.

The department is responsible for packaging products with the utmost care and taking into account all the requirements for safe future transportation of products.

This is the last step before the items reach the customer or the store shelf.

To the product of the factory attached:

packaging

labeling

individual tag

care features

instruction

stands and printouts

and other important details for pre-sale preparation

The pneumatic press allows you to realize a variety of design concepts and ideas on textiles.

A wide range of colors and shades can be used with this type of printing.

The department has designers who will adjust the layout and prepare the image for printing.

The maximum size of the image:

формат 28х36cm