Order from WP Merchandise

Choose the service you want to order:

Tailoring services

https://wpmerchandise.com/poslugi-z-poshittya-odyagu-en/

Services for sewing toys

https://wpmerchandise.com/poslugi-z-poshittya-igrashok-en/

Embroidery services

https://wpmerchandise.com/poslugi-vishivki-en/

Printing services

https://wpmerchandise.com/poslugi-druku-en/

Buy wholesale finished products

https://wpmerchandise.com/kupiti-gurtom-gotovi-virobi/

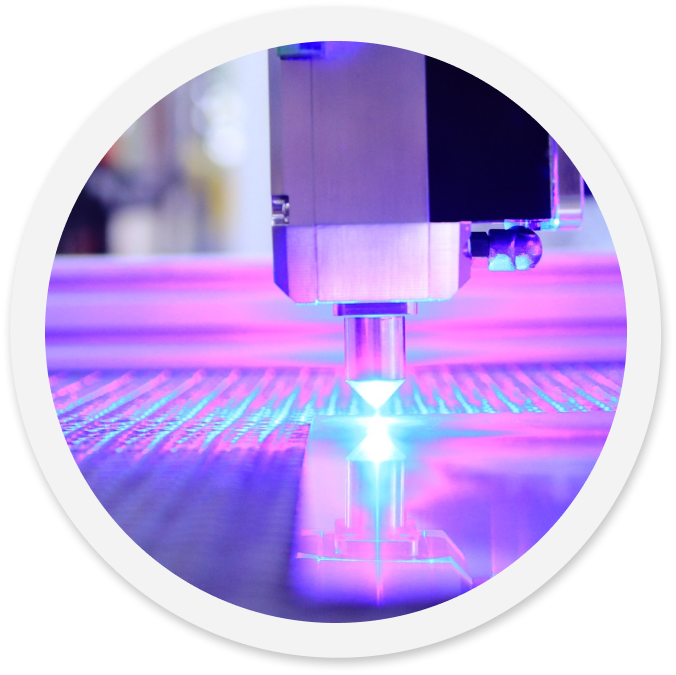

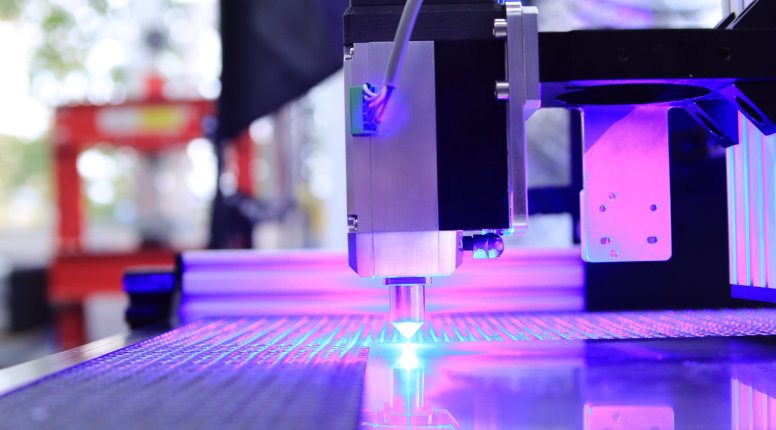

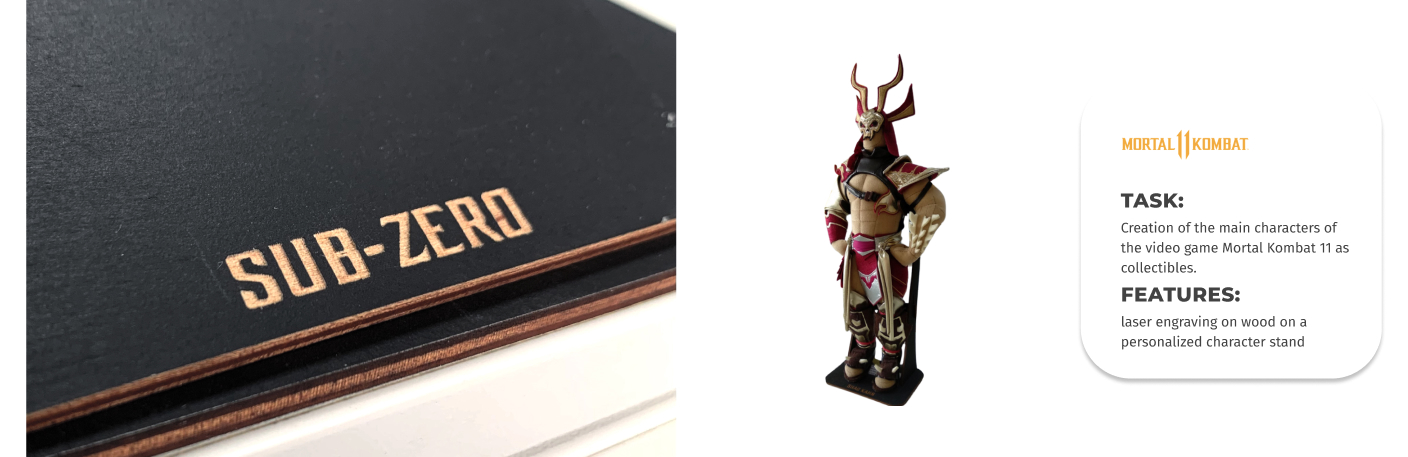

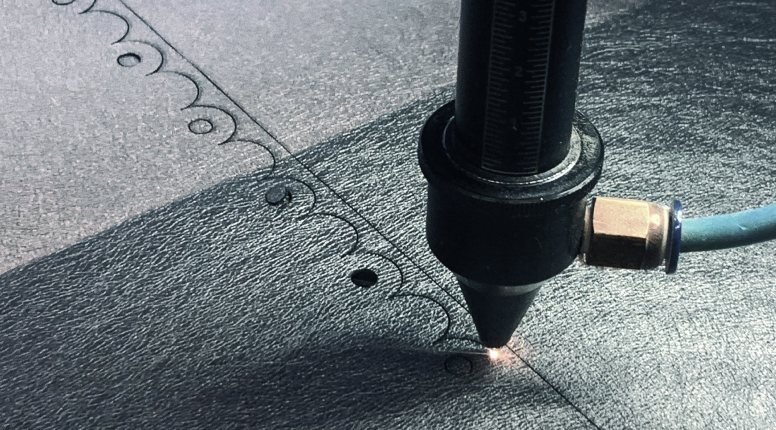

Laser cutting services

https://wpmerchandise.com/poslugi-lazernoi-porizki-en/

Development and design services by RnD department

https://wpmerchandise.com/poslugi-rozrobki-ta-dizaynu/